Paint Systems that Provide Greater Return on Investment

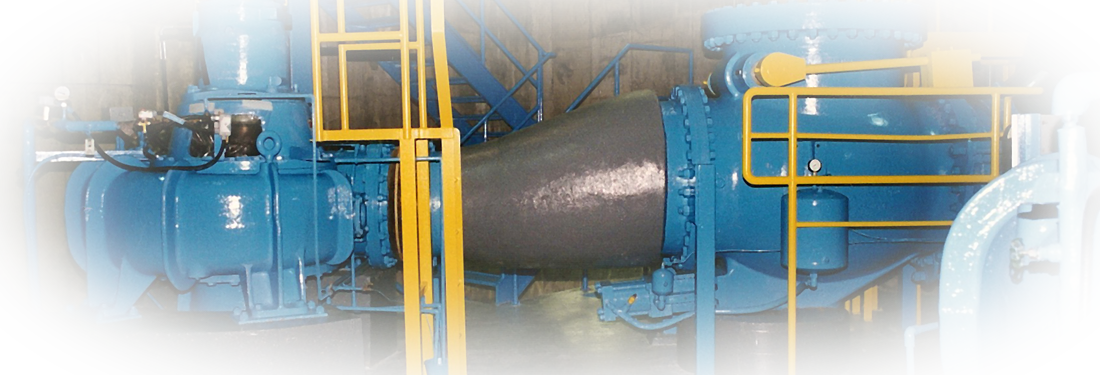

For high performance industrial paint applications, GLASS SHIELD combines maximum protection with flexible, cost-effective application characteristics for virtually any type of structure, transport vehicle or machinery.

- What does GLASS SHIELD durability mean to the customer?

- High gloss and color retention

- Impact resistance

- Chemical resistance

- U.V. resistance

- Corrosion control

- Lower cleaning and maintenance costs

- Better looking equipment

- Longer life expectancy of equipment

- Advantages to applicators include:

- Easy to apply (spray, brush or rollover clean, blasted or phosphated steel and many other substrates including aluminum, fiberglass and masonry)

- Quicker dry times for efficient job completion

- Excellent intercoat adhesion with subsequent coatings

- High build thickness (eliminates the need for additional coats)

- Low V.O.C. or V.O.C. compliant coatings

- Outstanding flow-out and hiding characteristics (approximately 30% more hiding)

- Easy access to technical support

GLASS SHIELD paints not only have remarkable chemical, impact and abrasion resistance, but they can also be custom formulated to meet specific project requirements for flexibility, elevated temperatures, thermal shock and other operating conditions.

GLASS SHIELD products are VOC compliant and safe to use with a variety of application techniques. They offer long term protection against mild and concentrated acids and alkalis, crude and refined petroleum products, aromatic and chlorinated solvents, and a myriad of other corrosive chemicals and environmental conditions.

To ensure you select the right product and application method for your project, you can rely on our network of approved distributors, trained and supported by GLASS SHIELD. Our knowledgeable experts are always available to assist you in evaluating your projects and future needs. For the approved GLASS SHIELD distributor nearest you, please contact our Customer Service Department at 1 800-361-6652.