our solutions by substrate | steel

Truck Boxes

1. Sandblast to obtain a surface profile of 1 to 1.5 mils complying with the standard SSPC-SP6 (commercial blast).

2. Apply one coat of EP-Guard epoxy primer 1500 Series for a minimal dry film thickness of 3 mils.

3. Topcoat with Glass-Guard polyurethane 2800 Series for a minimal dry film thickness of 3 mils.

Concrete Mixers

1. Sandblast to obtain a surface profile of 1 to 1.5 mils complying with the standard SSPC-SP6 (commercial blast).

2. Apply one coat of EP-Guard epoxy primer 1500 Series for a minimal dry film thickness of 2 mils.

3. Topcoat with Glass-Guard polyurethane 2800 Seriesfor a minimal dry film thickness of 3 mils.

4. For an additional super protection, apply one coat of clear one component acid resistant polyurethane MC-4250. (The procedure for adequate application of the MC-4250 : 1- Apply a very thin mist and let set for 30 minutes. 2- Then apply one medium wet coat.)

Salt Spreaders

1. Sandblast to obtain a surface profile of 1 to 1.5 mils complying with the standard SSPC-SP6 (commercial blast).

2. Apply two coats of anti-corrosion primer MC-4390 for a minimal dry film thickness of 5 mils (interior and exterior).

3. Topcoat the interior of the box only, with two coats of one component Amber Shield MC-4509.

4. Topcoat the exterior with two coats of Glass-Guard polyurethane 2800 Series to obtain a dry film thickness of 3 mils minimum.

Locomotives

1. Sandblast to obtain a surface profile of 1 to 1.5 mils complying with the standard SSPC-SP6 (commercial blast).

2. Apply one coat of EP-Guard 1500 Series for a dry film thickness of 3 mils.

3. Topcoat with Glass-Guard polyurethane 2800 Series for a dry film thickness of 3 mils.

Potable Water Tanks | Exterior

1. Sandblast to obtain a surface profile of 1 to 1.5 mils complying with the standard SSPC-SP6 (commercial blast).

2. Apply two coats of anti-corrosion primer MC-4390 to obtain a minimal dry film thickness of 8 mils.

3. Topcoat with Glass-Guard polyurethane 2800 Series to obtain a dry film thickness of 3 mils.

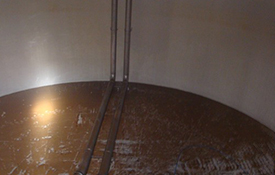

Potable Water Tanks | Interior

1.Sandblast to obtain a surface profile of 1 to 1.5 mils complying with the standard SSPC-SP5 (white metal blast).

2. Apply one coat of EP-Guard white epoxy primer 1553 to obtain a dry film thickness of 3 mils.

3. Topcoat with EP-Guard grey epoxy primer 1552 to obtain a dry film thickness of 3 mils.

Chemical Plants

1. Sandblast to obtain a surface profile of 1 to 1.5 mils complying with the standard SSPC-SP6 (commercial blast).

2. Apply two coats of one component anti-corrosion primer MC-4390 to obtain a dry film thickness of 6 mils.

3. Topcoat with Glass-Guard polyurethane 2800 Series for a dry film thickness of 2 mils.

Fire Hydrants

1. Sandblast to obtain a surface profile of 1 to 1.5 mils complying with the standard SSPC-SP6 (commercial blast).

2. Apply with a natural bristle brush two generous coats of anti-corrosion primer MC-4390 in order to obtain a dry film thickness of 4 mils. Let dry for 5 hours.

3. Topcoat surface with one or two coats of Glass-Guard polyurethane 2800 Series to obtain a dry film thickness of 2 mils.

Utility Trucks

1. Sandblast to obtain a surface profile of 1 to 1.5 mils complying with the standard SSPC-SP6 (commercial blast).

2. Apply one coat of one component anti-corrosion primer MC-4390 to obtain a dry film thickness of 3 mils.

3. Apply one coat of EP-Guard 1500 Series to obtain a minimal dry film thickness of 2 mils.

4. Topcoat with Glass-Guard polyurethane 2800 Series to obtain a dry film thickness of 2 mils.